Intelligent Logistics AGV Material Handling Equipment

material handling robot that navigates through QR codes and has safety protection functions.

Automobile Parts

Chapter 1 Product Overview

1.1 Main purpose and scope of application

This product is an intelligent warehousing robot, which is widely used in complex production and manufacturing scenarios. The self-developed core components have controllable costs, positioning cameras, control and drive all-in-one machines, equipped with different tooling and vehicles, and realize automatic material handling and loading and unloading. To meet the logistics needs of different industries and production processes, it is equipped with LCS logistics control system to meet the intelligent logistics and transportation needs of factories.

1.2 Product Features

1) Complete safety protection

Laser radar, photoelectric sensor, ultrasonic sensor, anti-collision strip, all-round safety protection.

2) Visualization of driving information and fault information

The industrial touch screen displays vehicle information in real time, driving status, and fault information is intuitive and clear.

Capacitive touch screen, simple and convenient operation and not easy to misuse.

3) Modular design

Each module is independent of each other, which is convenient for maintenance.

The material pallet rotary module can be selected as an expansion item to reduce unnecessary functional waste.

4) flexible and flexible

The positioning accuracy is high, the map is configured on demand, and the operation is flexible and flexible.

5) Diversification of industry applications

6) Convenient operation and maintenance, low cost

a) Site expansion can be deployed on demand, with low implementation difficulty, short cycle and low cost.

b) The robot can realize the cross-floor flow of goods, effectively reducing labor costs.

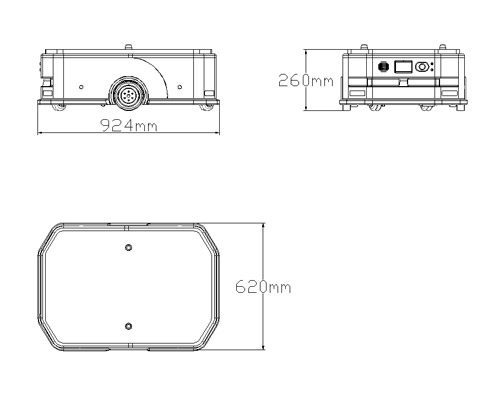

1.3 Product Appearance

The appearance of this product is shown in the figure.

1.4 Product Appearance Dimensions

LM-600 Latent Type AGV

|

LM-600 Latent Type AGV |

||

|

Basic parameters |

Navigation method |

QR code |

|

Load |

600kg |

|

|

Weight |

110kg |

|

|

Dimensions(mm) |

948mm(L)*600mm(W)*280mm(H) |

|

|

Sports performance |

Parking Accuracy |

±10mm,±1° |

|

Maximum straight speed without load |

≤1.5m/s |

|

|

Lift height |

≤80mm |

|

|

Lift duration |

≥2s |

|

|

Endurance |

Battery Type |

Lithium iron phosphate |

|

Battery parameters |

48V/30AH |

|

|

Full working hours |

≥8 Hours |

|

|

Charging Method |

Automatic Charging/Electric Charging |

|

|

Full charge time after emptying |

≤1.5h (calculated according to 10A; the charging time depends on the charging current) |

|

|

Number of charging cycles |

Fully charge and discharge 1500 times |

|

|

Safety performance |

Anti-collision |

1. Anti-collision radar with adjustable distance; 2. Front side 180-degree detectable <= 4m; 3. Rotation/reverse car detectable <= 1m; 4. Front and rear anti-collision strips |

|

Sound and light reminder |

Scenarios are not limited to going straight, failure, emergency stop, suspension, collision avoidance, idle, power shortage |

|

|

Emergency stop |

1. Front and rear emergency stop buttons; 2. Press the emergency stop to push; 3. Press the emergency stop to support wired control |

|

|

Easy of Use |

Shell replacement |

1. Support replacement of different shells before leaving the factory; 2. Support segmental replacement of shells (2 segments) |

|

Support handle control |

The control handle controls the AGV through a direct connection |

|

|

Remote switch |

Remote sleep, remote wake-up |

|

1.6 Product technical parameters

Table 1-1 Product Technical Parameters

Chapter 2 Quality Assurance

1.1 Quality Assurance

From the date of completion of equipment installation and signing of equipment acceptance (the signature of the responsible persons of both parties shall be no later than 30 days after completion of acceptance), provide a one-year quality guarantee for the whole machine. During the warranty period, all damaged or defective parts caused by the design of the equipment itself will be replaced free of charge (excluding improper use, force majeure), and the quality guarantee period of the replaced parts will start from the date of replacement for one year.

pennywang@wiiss.com

pennywang@wiiss.com

0086 17338110287

0086 17338110287