I-Factory Twins Application Solution (4): Iron and Steel Industry

Time:2023-04-23 Source: Click:

I-Factory Twins Application Solution (4): Iron and Steel Industry

Project Background

The client is the world's leading modern iron and steel conglomerate, one of the world's top 500 companies. It ranks second in crude steel output, first in automobile sheet output, and first in silicon steel output among listed steel companies in the world. It is the world's most complete carbon steel variety. One of the steel companies.

The iron and steel industry is the barometer of national economic development and the foundation for the development of industrial countries. However, the "blast furnace-converter" long-process production is still the mainstream production process of steel in my country. Converter steelmaking is an extremely complicated chemical reaction process, which cannot be seen or touched at all. Problems are based on experience and guesswork. Only through the Internet of Things , big data, visualization, digital twins and other technologies, 1:1 3D modeling of blast furnaces, and restoration of the real production process can speed up the transformation and upgrading of the entire industry.

To this end, Wiiss Technologies Co., Ltd built a digital twin platform for the steel factory for this customer.

3D visualization of a steel plant

Based on self-developed simulation technology and digital twin technology, Wiiss Technologies Co., Ltd simulates the production environment, process flow and equipment status of the steelmaking plant area in multiple dimensions, then renders and models all the objects, and replicates the steel plant area in equal proportions. Now, realize the visual display.

Intelligent operation and maintenance

I-Factory Twins platform integrates production data and equipment operation. Through AI processing and analysis, it displays information in different dimensions of the steel plant in the form of a visual table, presenting the current status of equipment operation, making it easy to query and trace, and to improve operation and maintenance.

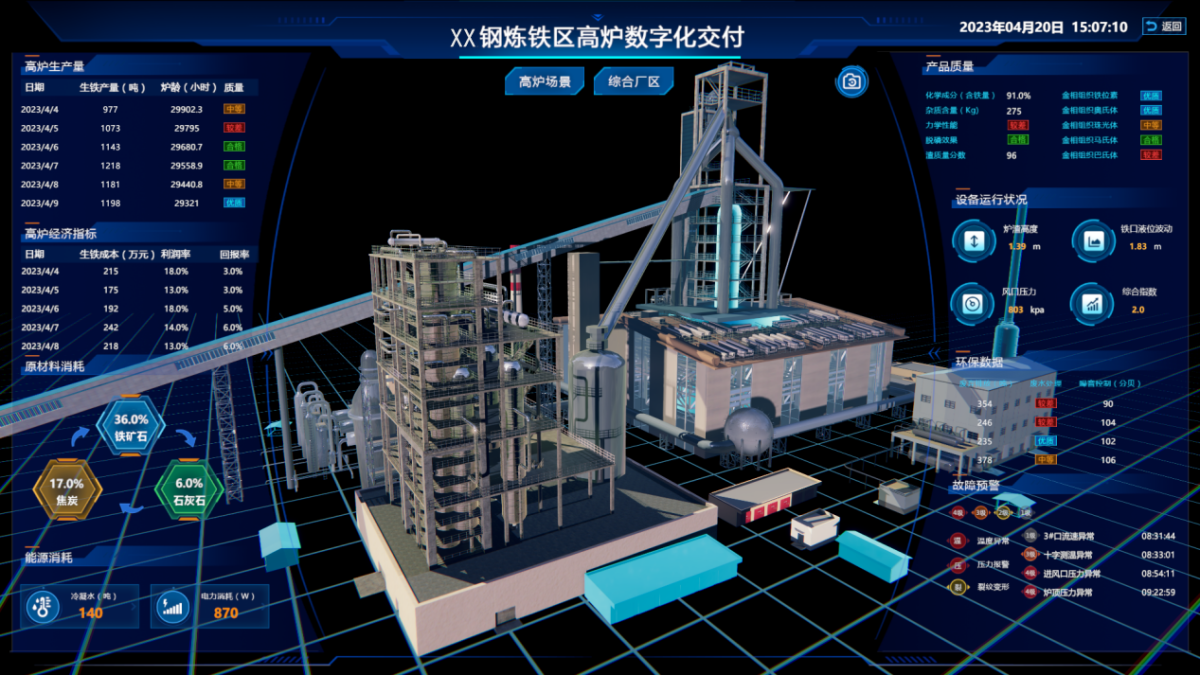

Function 1: Comprehensive management and control, mastering production status

It presents real objects with data, highly integrates various data information of the factory area, and conducts comprehensive monitoring and analysis of key indicators in the fields of factory assets, equipment, energy efficiency, and quality, so as to achieve more efficient and scientific factory management and comprehensively improve the management level of the factory.

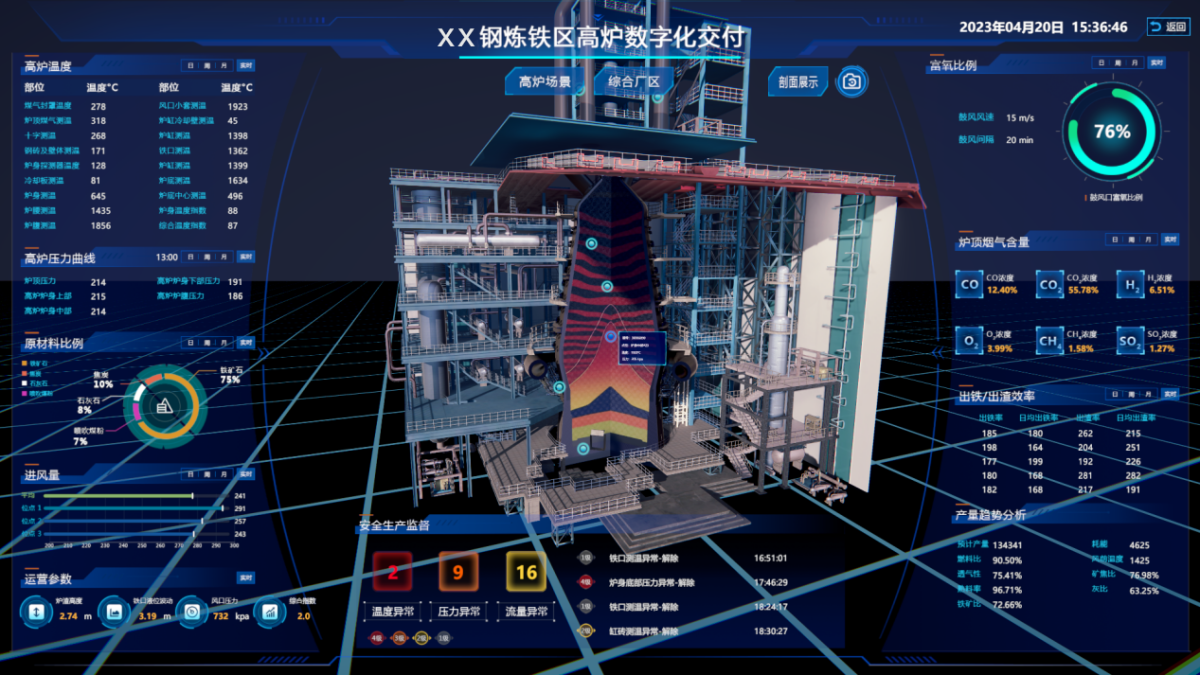

Function 2: blast furnace simulation, key equipment status monitoring

High-precision modeling based on i-Factory Twins technology, 1:1 reduction monitoring of blast furnace charging and smelting status, 3D modeling based on blast furnace process layout, including furnace shell, pipeline, furnace base refractory and water cooling, etc. The body and the air outlet correspond to a temperature measuring point respectively, focusing on displaying the three areas of the blast furnace body, furnace top winch feeding, and hot blast stove, reflecting the real-time status of materials and gases.

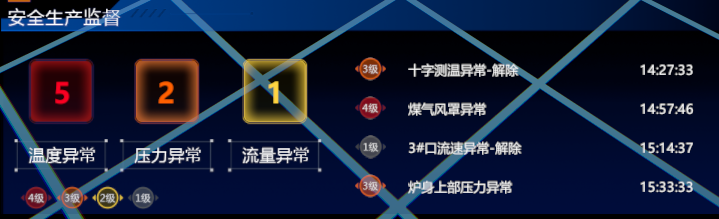

Function 3: Safety alarm, timely detection of abnormalities

Through the sensor collection in key areas of the blast furnace, the temperature, pressure, flow and other safety data of the blast furnace are obtained in real time. When the equipment runs abnormally, the system intelligently analyzes and sends an alarm message. And the alarm information is timed and classified, so that the staff can quickly identify and rush to the scene to solve abnormal problems in time.

Function 4: Environmental monitoring, early warning and reminder

The environment is the red line of normal production. I-Factory Twins system displays the data of the four major environmental systems simultaneously, namely waste discharge, wastewater treatment, noise control, and gas monitoring. According to the environmental monitoring data obtained in real time, the monitoring values of waste, dust, noise and various gases are displayed homogeneously in real time in the 3D twin scene, and pre-alarm prompts are given for points exceeding the environmental monitoring requirements.

Product value

Improve quality and efficiency: I-Factory Twins technology can help iron and steel enterprises provide data support in R&D design, production operation and maintenance, etc., so as to optimize resource allocation, rationally allocate production, and promote the improvement of product production quality and efficiency.

Model change: The production and manufacturing model has evolved from large-scale manufacturing to customized and predictive manufacturing, the equipment operation and maintenance model has changed from spot inspection and customized repair system to predictive maintenance, and the management method has changed from experience management to intelligent decision-making, etc.

Energy saving and emission reduction: With the help of digital technology exploration, better optimize the ratio of energy consumption, deepen the control of "carbon" emissions, and promote the realization of intelligent carbon reduction in the whole manufacturing process.

Conclusion:

Taking converter steelmaking as an example, this is an extremely complex chemical reaction process. Through digital twin technology, the whole process of steelmaking can be fully analyzed in the virtual converter. In this way, the root cause of cost reduction and quality improvement can be found fundamentally.

In the future, it will be the general trend to realize the digital transformation and development of the steel industry with the help of i-Factory Twins technology.

If any interested about i-Factory Twins, please dont hesitate to contact us

Email: pennywang@wiiis.com

Phone/WhatsApp: +86-17338110287

Previous:AGV Robot in Pharmaceutical Industry

Next:No article!

pennywang@wiiss.com

pennywang@wiiss.com

0086 17338110287

0086 17338110287